Copper is copper, right? A great conductor. Not the best (that would be silver), but 2nd-best works … especially when […]

Copper is copper, right? A great conductor. Not the best (that would be silver), but 2nd-best works … especially when considering cost and mechanical properties. (Why, oh why … do people pay for gold audio wires?)

From the “CRC Handbook of Chemistry & Physics“:

![Rendered by QuickLaTeX.com \[ \begin{array}{lr}Material & \rho \, , \, n\Omega \cdot m \\\hline1) \; silver & 15.9 \\2) \; copper & 17.1 \\3) \; gold & 24.4 \\4) \; aluminum & 28.2 \\\; tungsten & 56.0 \\\; nickel^* & 78.0 \\\end{array} \right. \]](https://davemcglone.com/wp-content/ql-cache/quicklatex.com-2e31e52f26e68d8d78978a1f2467ad5a_l3.png)

*Note: nickel is paramagnetic with relative permeability: ![]()

Although some form of copper is by far the most common conductor – wire – I’ve used both silver and nickel plated wires in my work. Silver’s about 10% more conductive than copper; nickel is about 4x less conductive – and has significant magnetic permeability as well. “Oops”on calculating electromagnetic propagation using the typical equations which assume a relative permeability of 1 (rather than 400 or so for nickel … when considering high-frequency skin depth on nickel-plated wire).

But let’s focus on copper. Specifically copper PCB traces.

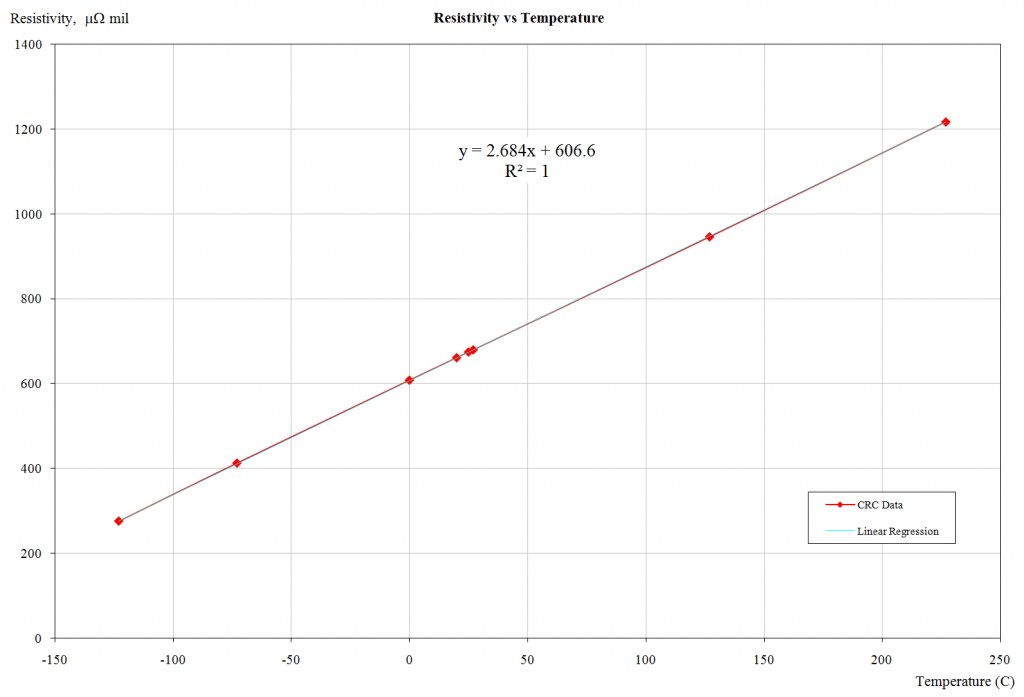

Current through a conductor generates heat. Usually this increase in temperature is minor but with a trend towards smaller geometries and higher current densities, I’ve found this to be a significant issue at times. Fortunately for those of us lazy enough to prefer simplicity, copper resistivity is pretty linear over a very wide temperature range as shown by this plot of resistivity vs. temperature.

Linear regression with R2 value of 1 between 150K and 500K (copper melts at 1356K). Fairly linear …

I’ve worked on circuits down to 77K (LN77 – liquid nitrogen) and up to about 600K (350°C – geothermal borehole) and the extrapolation of this curve seemed acceptable. But these are different measurement regimes with special requirements; let’s keep it reasonable.

[By the way and speaking of temperature, a rough rule-of-thumb: If you can keep your fingertip on a circuit for only a momentary count before “Ouch”, it’s running about 85°C. If “ouch” is instantaneous, you might have a thermal problem. Recall that package temperature is lower than junction temperature. If “ambient” is 25°C, I assume about 40°C (313K) for idling junction temperature.]

So the idea is to determine temperature change on a PCB trace. I used industry “standards”. I’ve not looked recently – I developed my own “calculator” several years ago … perhaps the expressions should be updated, but I suspect thermal properties have not changed much since then so I’ve not changed anything since I put these together. There are no corner corrections (corners will create a localized “hot” spot).

I would not guarantee “correctness” … but these estimations are not too far off and I still use them. It’s surprising how these seemingly little things can interfere with a good measurement (and this discussion doesn’t address thermoelectric effects such as those generated by multiple solder-copper contacts and vias). As usual, critical applications should require specific measurements on the actual circuit configuration.

The first parameter of PCB copper is weight: so many oz per square foot – often expressed simply as “1 oz copper” (which is “standard”). Depending on the PCB manufacturing house, variations between ¼ oz (maybe too light) to 4 oz (pretty heavy) may be available.

Copper thickness is 1.378 mil/oz/ft2

The resistivity of copper as a function of temperature may be expressed:

![]()

The standard expressions are based on empirical measurements defined in STD IPC-275 and IPC-2221A. Internal and external traces have different coefficients. These terms define an effective cross-sectional area related to some temperature change dT in °C.

![Rendered by QuickLaTeX.com \[ \begin{array}{lcc}\; & Internal & External \\\hlinek & 0.0150 & 0.0647 \\b & 0.5453 & 0.4281 \\c & 0.7349 & 0.6732 \\\end{array} \right. \]](https://davemcglone.com/wp-content/ql-cache/quicklatex.com-616427be75c3d1aae8f4ccf307727480_l3.png)

![]()

From this, the width necessary to limit dT to some defined value is as expected:

![]()

The trace resistance is now determined from:

![]()

Let’s look at an example. I’m to use 1 oz Cu. The internal trace will carry 100 mA and there should be no more than a 1°C temperature change. The ambient temperature is 35°C and trace length is 6″.

With variables I and dT, the effective cross-section area is 13.22 mil2. The trace width should be no less than 4.8 mil. The trace resistance will be 319 m![]() and voltage drop will be 31.9 mV.

and voltage drop will be 31.9 mV.

Well, I’ve kept the change in temperature low enough but that’s a large voltage drop. Try again.

Keeping the 6″ trace length with 100 mA current through 1 oz copper at 35°C, I want to keep the voltage drop to less than 10 mV. This requires the trace resistance to be less than 100 ![]() . Under these conditions, no more than 1 mW power will be dissipated in this trace. This time though, I’ll allow a 5°C temperature change.

. Under these conditions, no more than 1 mW power will be dissipated in this trace. This time though, I’ll allow a 5°C temperature change.

The resistivity of the copper will be:

![]()

and the minimum effective area is found to be 42.84 mil2 which requires an internal trace to be at least 31.1 mils wide. An external trace would only need to be 15.5 mil wide. Quite a bit different than that calculated in the first example.

One more example should do it …

Again, 6″ of 1 oz copper at 35°C. My trace is now 60 mil wide and carries 200 mA. This gives an area of 165.4 mil2.

The change in temperature is 0.12°C for an internal layer; insignificant for an external layer. Resistivity is 700.6 ![]() . The resistance is 25.4 m

. The resistance is 25.4 m![]() (4.2 m

(4.2 m![]() /in) with a total voltage drop of about 5.08 mV for either internal or external layer (about 0.85 mV/in). A squiggle over 1 mW will be dissipated.

/in) with a total voltage drop of about 5.08 mV for either internal or external layer (about 0.85 mV/in). A squiggle over 1 mW will be dissipated.

An estimate for trace capacitance in pF could be expressed as:

![]()

Concepts to consider for critical measurement circuits.